1、Why use RFID in cold chain transportation?

- 01. Temperature Monitoring: RFID tags with temperature sensors track temperature changes for perishable goods, maintaining the required conditions.

- 02. Data Accuracy and Traceability: RFID tags store and transmit product information, improving identification, traceability, and compliance.

- 03. Process Automation: RFID automates inventory management, product authentication, and quality control in the cold chain.

- 04. Enhanced Security: RFID provides anti-counterfeiting measures and safeguards against unauthorized access or tampering.

- 05. Exception Management: RFID alerts respond to deviations in temperature or critical parameters, minimizing damage and enabling timely action.

RFID temperature Sensor Logger Ads

A glimpse of the latest labels available

Currently there are 4 models of temperature tags developed here. We can customise different characteristics of temperature labels to meet your needs.

| Product Name | Type | Frequency | Application |

| Small size model | Active | NFC+UHF | Cold chain (real-time/offline storage) |

| Large size model | Active | NFC+UHF | Cold chain (real-time/offline storage) |

| UHF passive model | Passive | UHF | Cold chain (real-time storage) |

| ASYGN UHF passive model | Passive | UHF | Besides cold chain |

2. Features of RFID Temperature Sensor

Lightweight size

Same size as shipping label, thickness is only 0.7mm

Multiple presets

preset start time, temperature recording interval, high and low temperature alarm, etc.

Multiple storage methods

temperature data can be stored offline in the chip or uploaded to the cloud

Multiple reading methods

fixed reader, handheld reader or NFC-enabled cell phone scanning

Battery durability

Batteries can be customized to meet the lifetime of the product

Temperature recording range

-30C to +50C with 0.25C error value

Chemical Supplies

Medical Reagents

Frozen Foods

Refrigerated Food

3. Support various application

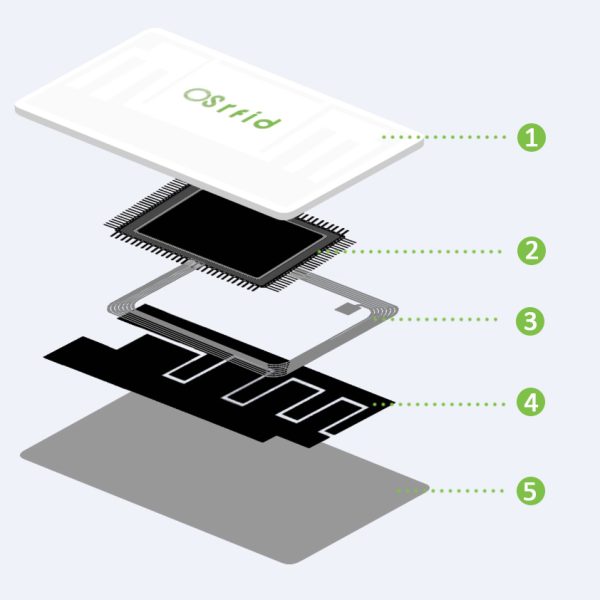

4. RFID temperature tag structure

Layer 1: Gloss or matt finish, blank or pre-printed

Layer 2: Temperature sensing chip. Other sense chips are available to add based on your needs.

Layer 3: This layer is Inlay, which contains the antenna and the chip.

Layer 4: Printed battery. This battery is standard for air transport

Layer 5: Standard glassine paper, polyester available

5. Customization services available

Custom printing: support a variety of printing processes, custom images, QR code and barcode printing

Antenna wire shape customization: the antenna can be designed into the shape of Logo

Chip customization: can customize high frequency, UHF, dual frequency chip, chip optional;

Customizable sensing function: other sensing chips can be added on the basis of temperature sensing chips

Customizable glue: M4 or permanent glue, repeatable glue optional

Writable code: writeable data, programmable

Customizable size: can customize the size of the label

Customizable material: customizable label face material

Convenience + Accessibility

Mobile Workplace

Management via APP

The temperature data of the items can be uploaded to the mobile APP, so that you can easily monitor the temperature change at any time.

NFC support

NFC-enabled cell phones can read the temperature data of an item by directly touching the temperature measurement tag.

Cloud remote monitoring

Data Integration to the Cloud

Temperature data of items, which can be stored offline or uploaded to the cloud. It is convenient for employees in the office to complete the remote monitoring of temperature data.

OSRFID can provide a complete set of RFID tagging solutions for the cold chain management industry, from cold storage management, cold chain transportation, to cold chain storage at the end, OSRFID can customize RFID tags for the corresponding scenarios. The current main RFID temperature measurement tag is a dual-frequency paper battery model. Later on, we will customize different specifications of temperature measurement tags according to customer needs.

[ Tips ]

OSRFID is a Chinese manufacturer with over 20 years of experience in the RFID industry, specializing in R&D of RFID inlays and tags. Our RFID labels have been exported to the world.

To explore more about our products, please download the lists below or contact us.

RFID temperature measurement tag function test

5. Why Choose OSRFID?

- OSRFID is one of the largest RFID inlay&label manufacturers in China

- OSRFID has a production capacity of one billion inlays per year

- OSRFID use the Mühlbauer DDA 40K WF to produce the RFID inlay

- OSRFID use the Voyantic Tagformance to test RFID inlay and label

- OSRFID can produce the eco-friendly RFID products.

- OSRFID has the strong chips supply chain, main RFID chips brands are our strategic partners.

- In addition, we can provide the euivalent/alternative chips to solve the chip shortage problem