I. Why RFID for Warehouse And Logistics Management?

- • Inventory accuracy is improved since RFID allows for real-time and precise inventory tracking.

- • Item tracking efficiency: RFID allows for simple scanning and finding of things in the warehouse.

- • RFID automates warehousing and logistics procedures, eliminating errors and speeding up operations.

- • RFID reduces manual labor by reducing manual tasks and freeing up labor resources.

- • Improved operational efficiency: RFID improves inventory management and productivity.

- • RFID enables real-time visibility and control for enhanced monitoring and decision-making.

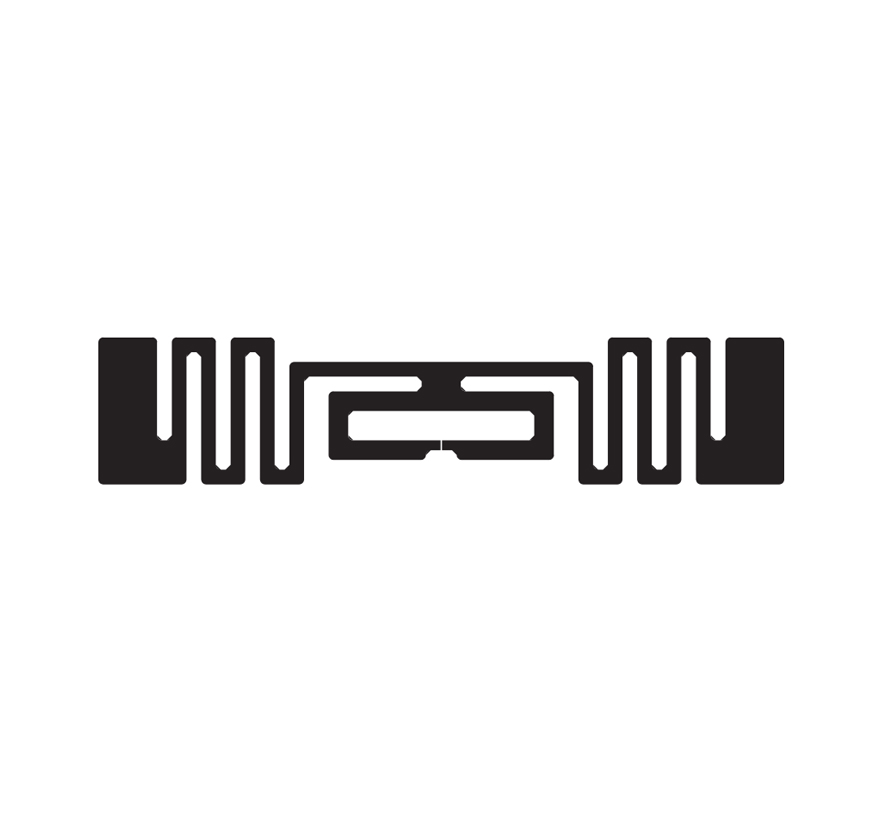

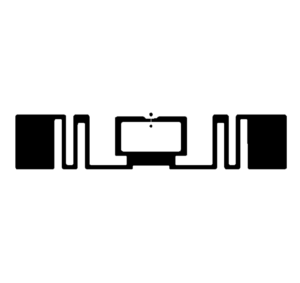

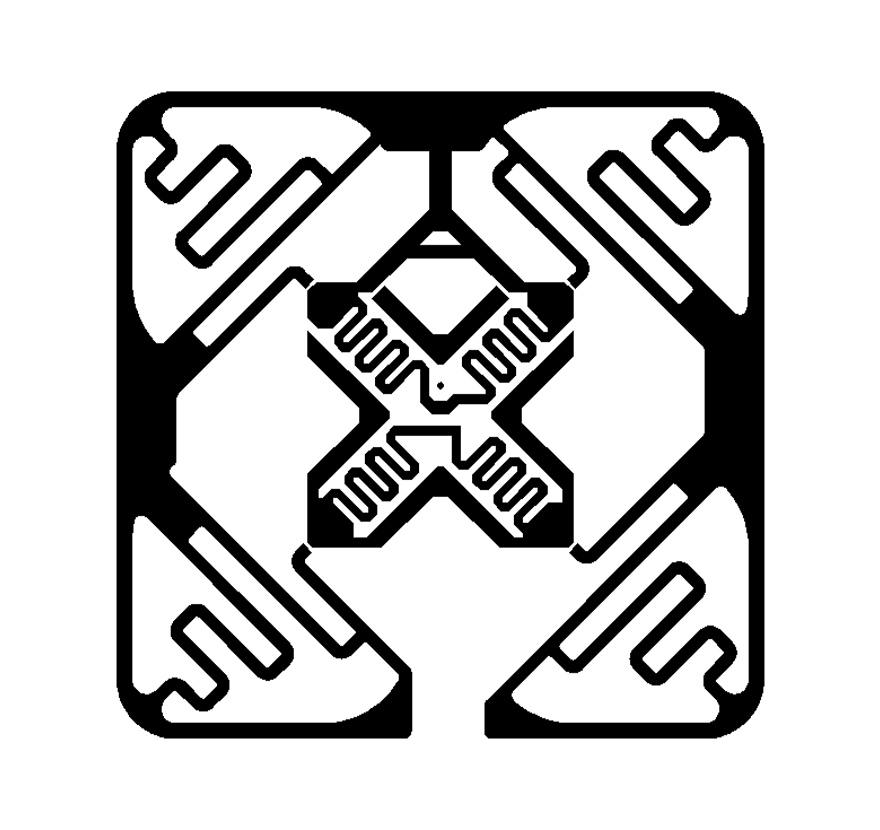

2. Hot-sell RFID Tag

OSRFID can design a wide range of RFID tags for warehouse inventory items management, suitable for all garment inventory, wine inventory, food inventory, etc. OSRFID can customize the chip, antenna, face material, etc. of the inventory tags according to your needs.

[ Tips ]

OSRFID is a Chinese manufacturer with over 20 years of experience in the RFID industry, specializing in R&D of RFID inlays and tags. Our RFID labels have been exported to the world. To explore more about our products, please download the lists below or contact us.

Warehousing and logistics is the core field of RFID technology. With the increasingly fierce competition, various enterprises are working hard to save costs and improve work efficiency. System integration is one of the main methods for enterprises to improve efficiency, but the system integration of various enterprises has always stayed on the IT system itself. As a bridge connecting the physical world with the existing IT system, RFID technology can effectively integrate the production and supply systems of the enterprise with the IT system of the enterprise. It can greatly improve the work efficiency of enterprises and enhance the competitiveness of enterprises. At present, the logistics management system usually uses barcode labels or manual documents to support the management of its own logistics links. However, the characteristics of barcodes, such as easy copying, no pollution, and no moisture resistance, and the tediousness of manually writing documents, are easy to cause Man-made losses make domestic logistics management, especially warehousing, always flawed.

With the application of the latest technology product of radio frequency electronic tags, it can fundamentally solve the above problems, realize the needs of automation, informatization and intelligence of enterprise logistics operations, and realize the integration of RFID technology and enterprise informatization system. Seam docking to ensure that RFID technology can maximize the benefits of enterprise logistics operations.

Technical Solution Realization

The logistics system is generally divided into four links: warehousing, inventory management, outgoing, and transportation. However, the RFID logistics system uses RFID tags as the support of the logistics system, so the embedding of RFID tags in the production process of goods is particularly critical. Embedding in the production process is a very critical first step in the RFID logistics system. After the introduction of RFID tags, the other four links of the logistics system can be closely linked based on RFID tags. In each link, the RFID system will play a powerful role, making the logistics of these items more efficient, accurate and safe.

The intervention of RFID in commodity production

The starting point of the traditional logistics system is warehousing or warehousing, but in the RFID logistics system, all commodities should have already started to implement RFID tags in the production process. Because in general logistics, most RFID tags are used in the form of self-adhesive labels, and it is only necessary to stick RFID tags on the item packaging. The RFID tag information entry is divided into four steps:

Describe the corresponding commodity information, including production department, completion, production process and responsible person, service period, project number of the target department, security level, etc. The comprehensive information entry of RFID tags has become a strong support for process tracking.

Enter the relevant information of the commodity into the corresponding RFID tag item in the database.

Edit and organize the products and the corresponding information to obtain the original information and database of the products. It should be noted that this is the first step in the logistics system and the first link in which RFID begins to intervene. It is necessary to absolutely guarantee this. Link information and RFID accuracy.

After completing the information entry, use the reader to confirm the information and check whether the information corresponding to the RFID tag is consistent with the commodity information; at the same time, perform data entry to display the completion time of the RFID tag information entry of each commodity and the person who handled it. In order to ensure the uniqueness of RFID tags, the information of the same products can be sorted and encoded to facilitate the inventory of the same items.

Realization of RFID in Commodity Warehousing

The warehousing requirements of commodities are very strict. There are three elements in the warehousing of traditional logistics systems that are strictly controlled: handling personnel, items, and records. This process requires a lot of manpower and time, and requires multi-layer inspections to ensure the three links. accuracy. In the RFID storage system, these three links can be efficiently and accurately controlled through the RFID information exchange system.

In the RFID warehousing system, through the reader at the warehousing entrance channel, the RFID tag of the commodity is identified, and the information of the corresponding commodity is found in the database and automatically entered into the RFID inventory management system. The system records and verifies the warehousing information. If it is qualified, it will enter the inventory information. If there is an error, it will prompt an error message. In the RFID inventory information system, the radio frequency terminal on the forklift can be directly guided to select the empty cargo space and find the best way to reach the empty space. Inventory information is updated as soon as the reader confirms that the item is in place. After the goods are put into storage, the storage list can be printed through the RFID system printer, and the responsible person can confirm it.

Realization of RFID in Commodity Inventory Management

After the goods are put into the warehouse, the RFID system needs to be used for inventory inspection and management. This link includes regular inspection of the classified goods through the reader, and analysis of the changes in the commodity inventory; when the goods are displaced, the RFID of the goods is automatically collected through the reader. Label, and find the corresponding information in the database, and automatically enter the information into the inventory management system, record the product name, quantity, location and other information, and check whether there is any abnormality. With the help of RFID system, the workload of personnel in traditional inventory management is greatly reduced, and commodity safety and efficient inventory management is realized.

Realization of RFID in Commodity Outbound Link

In the RFID outbound system management, the management system automatically determines the optimal delivery path and the delivery area according to the requirements of the commodity outbound order. The RFID system reminds the staff to load the goods through the on-board terminal. After scanning the RFID tags of the goods and the goods, the goods out of the warehouse are confirmed, and the inventory is updated at the same time. When the item reaches the exit channel, the reader will automatically read the RFID tag of the item, and call up the corresponding information in the database, and compare it with the order information. Except; if there is an abnormality, the warehouse management system will display a prompt message, which is convenient for the staff to deal with. The system prominently considers the coordination of logistics and information flow, and takes logistics as the entry point. And the material scheduling platform system composed of material scheduling platform software.